No matter what type of hydroponic system it is, hydroponic pumps more or less serve the same function. The pump pushes water from the hydroponic reservoir to the grow tray, where plants can then take in nutrients. Sizes, styles, and setups of pumps will vary from system to system, but the basic mechanics are the same.

How are hydroponic pumps rated or sized?

If you’ve just started looking at pumps for hydroponics, you’ve certainly noticed a few different types of ratings coming up. One of the most common ways to rate a pump is by gallons per hour, or GPH.

GPH basically just describes how many gallons of liquid the pump can move in an hour.

Another type of pump rating is PSI, or Pounds per Square Inch. Many hydroponic growers don’t see this rating unless they have a traditional, high pressure aeroponics system.

The last way that hydroponic pumps are rated is in Horsepower, or HP. This rating mostly applies to inline pumps, or pumps that are situated outside of the hydroponic tank. Pumps rated in HP are used for larger grow operations. At a certain point, the GPH ratings get so large, that it doesn’t make sense to keep measuring by GPH. That’s why many commercial operations use pumps rated in horsepower.

Types of hydroponic pumps

You’ll see a variety of different styles and manufacturers for hydroponic pumps. However, there are still two main types to choose from.

Inline pumps

Inline pumps are placed outside of the hydroponic reservoir. They should never be placed underwater. The pump is connected outside of the tank, with a motor put into a separate encasement. Systems larger than 1,000 gallons are better suited to inline pumps. Because of their high capacity, inline water pumps are often used for commercial hydroponics.

Submersible pumps

Submersible pumps are placed right in the hydroponic tank. Systems between 1,000 to 1,200 or less are best suited to submersible pumps. With fittings and tubing, nutrient solution is transported to the grow tray. Pretty much any non-commercial grower will use a submersible water pump.

We recommend this submersible pump

Essentials of hydroponic pumps

Before you start selecting and sizing a hydroponic pump, you need to know the basics. We already know that pumps work to move nutrient solution, or hydroponic water, to the plants. We also know how pumps are measured: either with GPH, HP, or PSI.

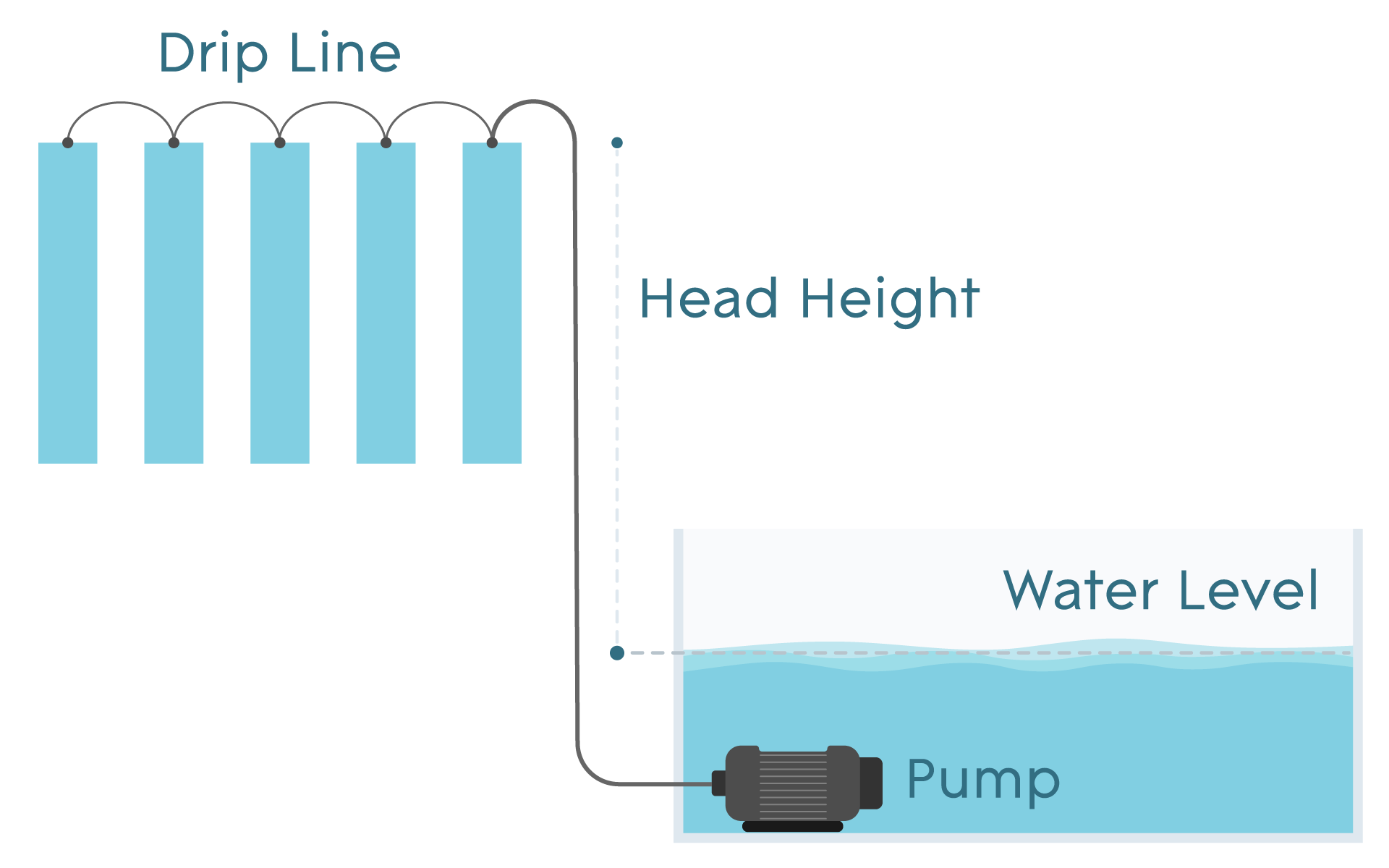

When water moves upward, it loses some of the power that the pump supplies to it. The higher the water has to travel, the less force it has behind it . The pressure that inversely affects liquids moving upward from a water pump is called back pressure. Back pressure is basically a result of the weight of the water itself, and gravity.

What you really need to remember is that the higher up you need to move your water, the less GPH your pump can move.

After above a foot of elevation, GPH starts decreasing. Since few people have their hydroponics systems set so close to ground level, manufacturers include handy charts to help. The Maximum Head Height or Maximum Lift tells you how high up the pump can move water. For some pumps this could be 5 feet, for others it could be significantly more. Most water pumps include something like a flow and height chart. This shows you the efficiency of a pump, at different elevations.

For instance, a pump may be rated as 50 GPH, but at a height of 5 feet, the GPH lessens to 30 GPH.

Choosing a flow rate

With back pressure and elevation in mind, it’s a good idea to figure out how many GPH you need, your budget, and choose the pump with the tallest head height. Most pumps for hydroponic systems end up losing between 15-30% efficiency when all’s said and done.

Once you know how many GPH you need circulating in your hydroponic system, the water pump is the simple part. Most people even double the minimum they need for good measure.

Another thing to understand is not all pumps come with a solid GPH flow rate. There are plenty of hydroponic pumps that have a GPH range listed, rather than one number. When they have more than one GPH rate listed, it’s usually because different flow adapters are included.

So if you see a pump listed as 100-300 gph, the smaller adapter creates a 100 gph flow rate, while the larger creates a 300 gph flow rate.

You can always reduce flow,

but you can’t make a pump work harder than it’s made to.

Sizing your pump

You can’t size a hydroponic pump if you don’t know how big your system is. Stumped about how much water should circulate through your hydroponic system? You can learn more about sizing hydroponic tanks here.

For now, here’s a quick refresher:

- Small plants need ½ gallon of water each

- Medium plants need 1 to 1 ½ gallons of water each

- Large plants need 2 ½ gallons of water each

You can use these figures to estimate how much water each plant needs. Just add the water needs of each plant together, and that’s the minimum your reservoir should hold. Much like with pump sizes, it’s always a good idea to double your minimum requirements.

Now, you should have an idea of how much nutrient solution should circulate throughout your hydroponic system. Next, it’s time to figure out how often that nutrient solution fully circulates.

Figuring out how many GPH you need

Each type of hydroponics system feeds plants slightly differently. A drip system with a 50 gallon reservoir won’t need to circulate water as frequently as an NFT (Nutrient film technique), system with a 50 gallon reservoir. While not every system needs the same amount of water flow, you can still figure out a general figure.

If you’re not sure exactly how much nutrient solution you need circulating (or how often), aim for a full circulation every two hours. In plain English, what does that mean? You want the full amount of your hydroponic reservoir to move through your system. And you only want it to take about two hours to do it.

Sizing hydroponic pumps – an example

For this example, let’s say you have a 50 gallon reservoir. And let’s assume you want it to fully circulate every two hours. Just use simple division and divide your reservoir volume in half.

50/2=25

Basically, you need to pump 25 gallons per hour if you’re running a two hour cycle.

This is a good rule of thumb to use to get a baseline for how many GPH you need in a hydroponic pump. However, depending on the size and type of your system, as well as your plants and ambient conditions, that number will vary.

One system that needs to be measured a little differently is an ebb and flow system. You’re not constantly circulating nutrient solution, so a GPH rating doesn’t help you much. To size a pump for an ebb and flow system, you first need to know how long your flood intervals are. Then, you need to measure the height of your optimal water level and do some simple math.

Ebb and flow, or flood and drain, systems are flooded in intervals of minutes, not hours. If you have a system with one flood tray, or chamber, it’s a little easier. Take the number or gallons you need to flood your system. Then, you need to figure out how many gallons per minute a pump can move. To get this number, just take the pump’s GPH, and divide by 60. This lets you know exactly how much water moves every minute.

Here’s an example of how to size a pump for an ebb and flow system:

Let’s assume you need 5 gallons to fill your flood table. Then, let’s assume you want it to reach the fill line within 10 minutes. With these numbers, we know that you need at least ½ gallon moving every minute.

5/10= ½

Now, you need to figure out the GPM, or gallons per minute, of the pump, as it translates to GPH.

We already know you need a flow rate of ½ gallon per minute. We can reverse the equation (rather than dividing by 60 to see if a pump is suitable), and determine the size of a pump you need to buy. So, we’ll take our ½ gallons per minute, and multiply by 60.

1/2 (gallon) x 60 (minutes) = 30.

Basically, you need a 30 GPH pump to get your 5 gallon flood tray to fill within 10 minutes.

What if your pump is too powerful?

Like we discussed earlier, it’s far better to have a more powerful pump. You can always dial down the flow rate, but you can’t make a 50 GPH pump run like a 100 GPH pump.

So how exactly do you adjust the flow rate for hydroponic pumps?

First, get some extra tubing and a ‘T connector.’ Attach the T connector to the end of the tubing that connects your pump to your grow tray. Attach additional pieces of tubing to each end of the ‘T.’ One tube will lead to your plants, just like the original did. The other tube will lead directly back to your hydroponic reservoir. With nutrient solution directed to two different streams, the flow rate is now lower.

If using a T connector to direct some nutrient solution back to your reservoir isn’t lowering the flow rate enough, there’s another option. Keep the same setup with the T connector and tubes that lead to your plants and reservoir. Then, install a valve in between one end (or both ends) of the connector and the tubing. Adding a valve allows you to fine tune the flow rate, and once it’s installed, it’s easy to adjust whenever you need.

Frequently asked questions

What kind of pump do I need for a DWC system?

DWC (deep water culture) and Wick systems are different from other hydroponic systems when it comes to the pump. Neither of these need a typical ‘water’ pump. In fact, a wick system doesn’t really need one at all. However, a DWC system does need an air pump. The air pump is attached to an airstone or aquarium bubbler. Then, tiny air bubbles diffuse from the airstone, giving roots plenty of oxygenation in their water.

Where do I find valves for my hydroponic pump?

Valves are available in a ton of places. Of course, you can order one online, just make sure you check the size so it fits your tubing. If it doesn’t fit snugly, you’re asking for a leak. You can also buy valves at your local home improvement and gardening store, or even the fish aisle in your local pet store. Gang valves are also available for attaching multiple tubes to a single main valve.

How do I clean my hydroponic pump?

If you’re using a submersible pump (and most non-commercial growers do), then you’re in luck. Because the entire pump can be immersed in liquid, it’s a lot easier to clean. You don’t need any special materials either. Just use the same solution that you use to clean your reservoir. A 50/50 mix of either vinegar and water, or hydrogen peroxide and water is inexpensive, and effective. Soak your pump in the solution for a few minutes, then wipe it down (including all components). Then, rinse any remaining solution off the pump, and dry it off.

Do I need a water pump for my system?

Most hydroponic systems do need a water pump. Of course, water pumps aren’t required for every system type. For example, DWC and wick systems don’t need a water pump. That said, most other types do need a pump. Ideally, a submersible water pump. So, if you have an NFT, ebb and flow, drip, or aeroponic system, you need one. Without water pumps these systems simply can’t achieve any real water flow. Remember, plants need the nutrients in hydroponic water (nutrient solution). A water pump creates the force needed to move nutrients from the reservoir, and to the plants.